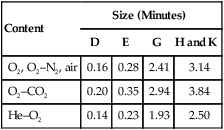

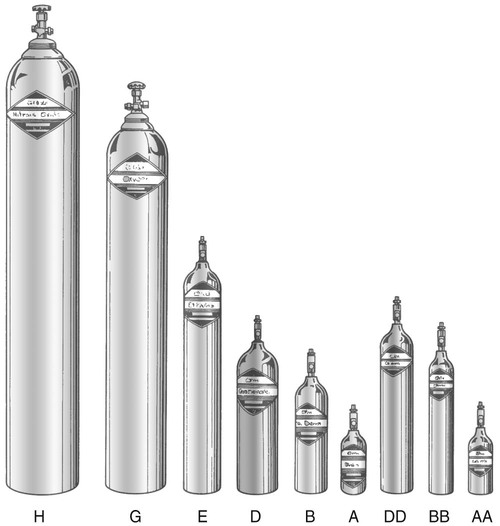

1. Identify common therapeutic medical gases. 2. Describe how to store, transport, and safely use compressed gas cylinders. 3. Describe how oxygen is produced. 4. Use the oxygen cylinder safely. 5. Calculate the duration of flow of a compressed oxygen cylinder. 6. Describe common safety indexing safety systems. 8. Calculate the duration of flow of a liquid oxygen cylinder. The therapeutic use of medical gases is a fundamental part of respiratory care. Many gases are commercially produced, but only a few are used in the respiratory care of patients. The most common ones are listed in Box 14-1. Therapeutic gases are used daily by the respiratory therapist (RT) to relieve symptoms and improve the oxygenations of patients. Oxygen is the most commonly used medical gas by RTs, and its uses are described in detail in Chapter 15. Care must be taken when dealing with medical gases. Understanding how cylinders work, how to safely store and appropriately use them will be discussed in this chapter. Oxygen concentrators will be discussed in Chapter 29. Ensuring the correct gas is given to the patient is a safety priority. Gas cylinders are identified from their label and color. If the label and color do not match, the cylinder should not be used. The color codes for medical gas cylinders in the United States are given in Table 14-1. Reducing valves are needed to decrease the pressure of the cylinder to 50 pounds per square inch (psi), the standard working pressure for respiratory equipment. The American Standard Safety System (ASSS) provides standards for threaded high-pressure connections between large compressed gas cylinders and their attachments. Smaller cylinders (up to and including E size tanks) utilize a division of the ASSS, called the pin-indexing safety system (PISS), which helps avoid unintended misconnections between pieces of equipment. Figure 14-1 illustrates the different cylinder sizes available. Typically found at the station outlets of central piping and at the inlets of blenders, flowmeters, ventilators, and pneumatically powered equipment, the diameter-index safety system (DISS) helps prevent the interchange of medical connectors that are less than 200 pounds per square inch gauge (psig). To determine the duration of gas flow (also referred to as duration of supply) for a compressed oxygen cylinder a calculation must be done. The cylinder factors for common cylinder sizes are provided in Table 14-2. This formula is given in Box 14-2. The following is the step-by-step process for using an oxygen cylinder. TABLE 14-1 Color Code for Medical Gas Cylinders for the United States TABLE 14-2 Cylinder factors for Calculation of Cylinder Duration of Flow 1. Release the safety strap or chain. 2. Move the cylinder onto the cart safely, and secure it. 3. Move the cart to the desired location for delivery of gas. 4. Secure the cylinder in the new location, if removing it from the cart. 5. Remove the protective cap or wrap. 6. Ensure the safety of bystanders by turning the valve away from the persons present. 7. Give a verbal warning of cylinder being cracked. 8. Visualize the valve or regulator inlet to confirm that it is contaminant-free. 10. Connect the regulator to the cylinder firmly, and open the cylinder. 12. Following use, close the cylinder valve, bleed, and disconnect the regulator. 13. Place the safety cap back on the cylinder, and return it to the appropriate storage location.

Storage and Delivery of Medical Gases

» Skill Check Lists

14-1 Using an Oxygen Cylinder

Oxygen

Green

Air

Yellow

Nitrogen

Black

Helium

Brown

Nitric oxide

Teal and black

Carbon dioxide

Gray

Helium–oxygen

Brown and green

Carbon dioxide–oxygen

Gray and green

Content

Size (Minutes)

D

E

G

H and K

O2, O2–N2, air

0.16

0.28

2.41

3.14

O2–CO2

0.20

0.35

2.94

3.84

He–O2

0.14

0.23

1.93

2.50

Implementation

Storage and Delivery of Medical Gases