Process

Never a problem

Sometimes a problem

A problem about ½ the time

A problem most of the time

Always a problem!

Patients and Families have concerns

Line Infection prevention

Surgical site infection prevention

Pain management

Hand-off from OR

Discharge instruction

Training the Team

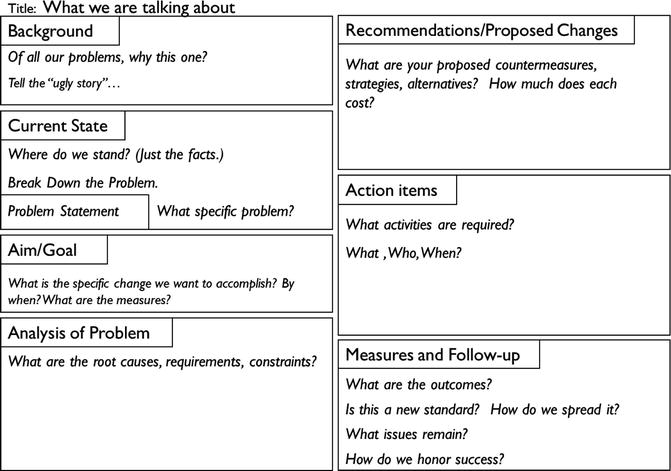

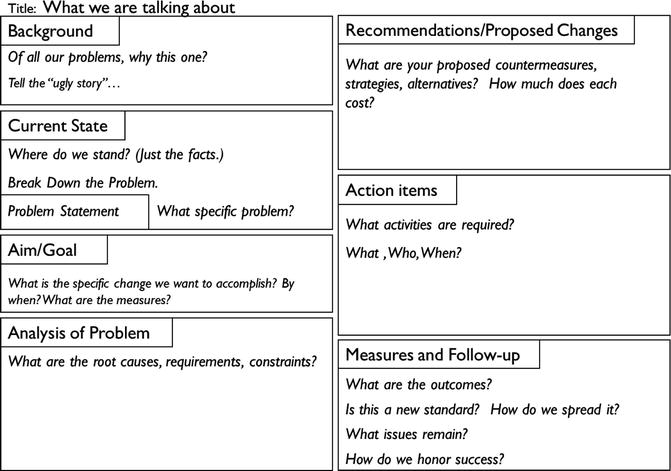

Team members likely have varying experience and knowledge of improvement techniques. To level-set and ensure team members are adequately prepared to do and lead improvement work, formal preparation should ideally be together. Training typically includes didactic lessons on education and improvement methodologies. More importantly and realistically, training should occur in “real time” and revolve around the problem selected. By receiving “in the moment” coaching with a relevant problem within the unit enhances success and promotes credibility of the LIT. There are many improvement methodologies including the Toyota’s 8-Step Problem Solving [10] (Table 21.2) and A3-thinking [9] (Fig. 21.1). These improvement modalities are based on the Shewhart PDCA cycle [10]. Table 21.3 highlights an example to integrate improvement methods into a training program.

Problem solving steps | Processes for each step | |

|---|---|---|

Plan | 1. Clarify the problem | 1. Identify the ultimate goal |

2. Identify the target condition (interim goal) | ||

3. Identify the gap between the target condition and current state | ||

2. Break down the problem | 1. Break the problem down | |

2. Select the specific problem to solve | ||

3. Specify the point of cause (go and see—who, when, where, why, how is it happening?) | ||

3. Set aim/target | 1. Commit to solving the problem | |

2. Set a measurable, concrete, challenging, time specific target/aim | ||

4. Root cause analysis | 1. Without preconception, consider as many potential causes as possible | |

2. Based on facts gathered by going and seeing, keep asking “why?” | ||

3. Specify the root cause | ||

5. Develop countermeasures | 1. Develop as many as possible | |

2. Narrow down to the most practical and effective | ||

3. Build consensus with others | ||

4. Create a clear and detailed action plan | ||

Do | 6. See countermeasures through | 1. As a team, implement countermeasures (changes to test) quickly |

2. Share progress by following reporting, informing and consulting communication practices | ||

3. Never give up, and proceed to the next step quickly | ||

Check | 7. Monitor results and process | 1. Evaluate the overall results and the processes used, share evaluation with involved team members |

2. Evaluate from three viewpoints: patient (customer), hospital, yours | ||

3. Understand factors behind success or failure (learn) | ||

Adjust | 8. Standardize successful processes | 1. Structure successful process (standardize) |

2. Share new precedent through horizontal deployment | ||

3. Start next the round of incremental improvement | ||

Table 21.3

Example LIT training program

Day 1 | Day 2 | ||

|---|---|---|---|

Time | Topic | Time | Topic |

0:15 | Team dynamics [12] | 0:30 | Data analysis and measurement [3] |

0:10 | 0:30 | Exercise: develop measures | |

0:10 | 0:20 | ||

0:30 | 0:30 | Exercise: Plan your tests of change | |

0:20 | Clarifying and breaking down problems: understanding current state [9] | 0:20 | |

1:30 | Exercise: go to the workplace and see (who, what, when, where, why does the problem happen?). Use timers, spaghetti diagrams, etc. as needed | 0:30 | Exercise: plan how to use A3 thinking to gain agreement, test changes, fill out A3 |

1:00 | Exercise: debrief, draw current state map, record all data, give shape to problem | 0:15 | |

0:10 | Specifying the problem to solve: set target [9] | 0:30 | Managing standards: Daily management system overview [20] < div class='tao-gold-member'>

Only gold members can continue reading. Log In or Register to continue

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree

Get Clinical Tree app for offline access

Get Clinical Tree app for offline access

|