15

Automobile maintenance, repair and refinishing

15.1 Introduction – the industry

The repair and maintenance of cars and trucks is a worldwide industry, as anywhere automobiles are driven there is a need for maintenance and repair workshops. Unlike the production of automobiles, repair and maintenance generally occurs in small workshops, even when incorporated into a car dealership. Relatively few epidemiology studies have been performed on this workforce, in part undoubtedly due to the typical workplace – small independently owned car maintenance and repair workshops. Workers in the larger workshops are usually more specialized, and these larger premises are more likely to have industrial hygiene controls and protective equipment. A different spectrum of exposures and occupational lung diseases is seen in the automobile maintenance and repair industry compared with the primary manufacturing of vehicles.

Maintenance repair workshops may cover general engine repairs or specialize in certain repair work, such as radiators or transmissions. It is important to differentiate maintenance workshops from collision repair workshops or auto body repair workshops, which have additional unique exposures. Worker titles may assist in this distinction: a mechanic or service technician generally works on engines and mechanical repairs; auto body technicians may perform much of the same engine/mechanical work, but usually also do structural repairs and some painting. Painters are responsible for spray painting in body workshops. Smaller workshops may not have dedicated painters.

Trucks and buses are usually maintained and repaired in separate facilities given differences in types of engines (diesel and biodiesel vs gasoline) and large scale. The types of respiratory hazards are similar, although spray painting large vehicles, especially if an appropriate sized spray booth is not available, can involve greater exposures.

15.2 Exposures from automobile maintenance and repair

Exposures in car and truck engine repair and maintenance workshops are myriad and variable. Repair of clutches and brake linings can entail exposure to asbestos and solvents such as n-hexane which can cause peripheral neuropathy. Cases of mesothelioma have been reported among brake and car mechanics. Working on batteries may expose a worker to lead from the lead battery plates. Batteries also contain sulfuric acid. Radiator repair can also result in lead exposure, unless the radiator is lead-free.

Welding, grinding and cutting metal engine parts can produce metal fumes, aerosols and particulates in the air. Other maintenance and repair work includes exposures to fuels, degreasers and various solvents. An engine running inside a workshop without sufficient ventilation can produce carbon monoxide and also diesel and gasoline exhaust fumes.

15.3 Exposures in auto body workshops

In addition to the exposures in car maintenance workshops, auto body workers are also exposed to a number of other hazards. Grinding, sanding, cutting and occasionally sandblasting of metal parts occurs in auto body repair work, resulting in dust that can contain heavy metals, various particulates and potentially silica. Old paint may be removed with solvents such as methylene chloride, which along with n-hexane is neurotoxic, and is being replaced by less toxic solvents.

Resin or putty such as ‘Bondo’, which typically contains a polyester resin, styrene, and talc, is commonly used as a plastic body part filler. Workers mix Bondo with a hardener, apply it to the damaged body part, and then sand it after it hardens, which can generate substantial irritant dust exposures.

After cars are structurally repaired, the last step is to apply a new durable finish, comprising several layers of sprayed-on two-part polyurethane coating. These paints typically contain aliphatic diisocyanates, primarily polymeric hexamethylene diisocyanate (HDI) or isophorone diisocyanate (IPDI) dissolved in solvents such as acetone, toluene, xylene and methyl ethyl ketone. The isocyanate part is mixed with a B part containing the polyol, catalyst and other ingredients. Solvents are also used to wipe down a car prior to re-painting, usually hand-applied with a cloth or sprayed, and during clean-up. Several coats of primer and sealer are typically applied, followed by the color coat (basecoat) and finally the protective top coat (clear coat) is applied in several layers. The color coat usually does not contain isocyanate; the clear coat almost always contains isocyanate, which imparts the hard finish that is impervious to ultraviolet rays.

Spray painting entails the highest risk of respiratory and skin exposure to isocyanates, but isocyanate exposures can occur with other job tasks and as a bystander. Skin exposure is particularly of concern with isocyanates, since such exposure probably is an effective route of sensitization. Skin exposure can occur from deposition of airborne exposures on skin, and also in settings where airborne exposures are generally well controlled, such as paint mixing, spills or contact with products that are not fully polymerized, such as compounding and polishing after the final paint coating, or from tasks that generate heat and thermal degradation products, such as sanding of coated parts. Skin exposure to isocyanate typically does not cause rashes or other warning symptoms that might reduce exposure.

Auto body workshops are generally required to have a booth for spraying paint, but many still do not, or spray painting occurs outside the booth. Other ventilation systems for sanding, welding and mixing paint are also important, but may be absent, especially in smaller workshops.

Personal protective equipment (PPE) whenever spraying paint should include an appropriate respirator, gloves and full skin covering – paint suit or long sleeves, head covering, as well as eye protection. For small paint jobs, workers may be less inclined to wear PPE. Gloves should be worn when using body filler, for all sanding, and when there is hand contact with fresh paints. Particulate filtered respirators are needed against dust and organic vapor filters should be used for solvent exposures. Appropriate respiratory and skin protection should also be worn for welding, grinding and cutting, and any other work with lead or solvents.

15.3.1 Spray-on truck-bed liners

Following a worker’s death, the US National Institute for Occupational Safety and Health (NIOSH) issued an alert regarding the application of spray-on truck bed liners, a 2-part polyurethane coating product which is sprayed on the inside of truck beds. The liner coatings typically contain methylene diphenyl diisocyanate (MDI), an aromatic isocyanate that is commonly used to make polyurethane foams, coatings and adhesives for use in many industries. Although less volatile than HDI and TDI, similar precautions must be taken regarding use of ventilation and appropriate PPE especially when MDI is sprayed or heated.

15.4 Respiratory diseases in auto mechanics and repair workers

The most important occupational lung disease in automobile mechanics and auto body repair workers is work-related asthma, either exacerbation of pre-existing asthma secondary to the multiple irritant type exposures or new-onset asthma due to irritant, or more commonly, sensitizing agents. Non-asthmatic irritant and allergic responses, including upper airway irritation, eye symptoms and rhinitis are also common. By far the most common sensitizing agents in this industry are the isocyanates used in the polyurethane paints and truck-bed linings. Carbon monoxide poisoning can occur from idling vehicles.

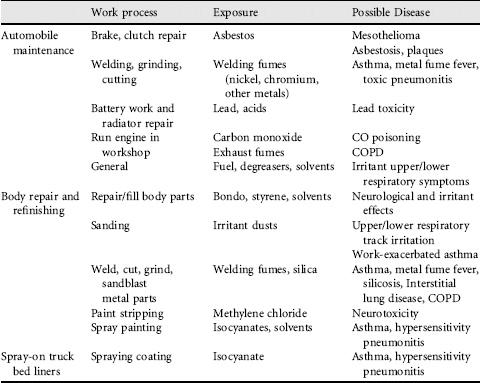

Less common diseases include acute pneumonitis, hypersensitivity pneumonitis and mesothelioma related to brake linings. There is limited data suggesting that chronic exposures may increase risk for chronic obstructive pulmonary disease (COPD) and interstitial lung diseases (Table 15.1).

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree